– Pre-commissioning cleaning

– Flushing

– Air or nitrogen blowing

– Pigging

– Chemical cleaning

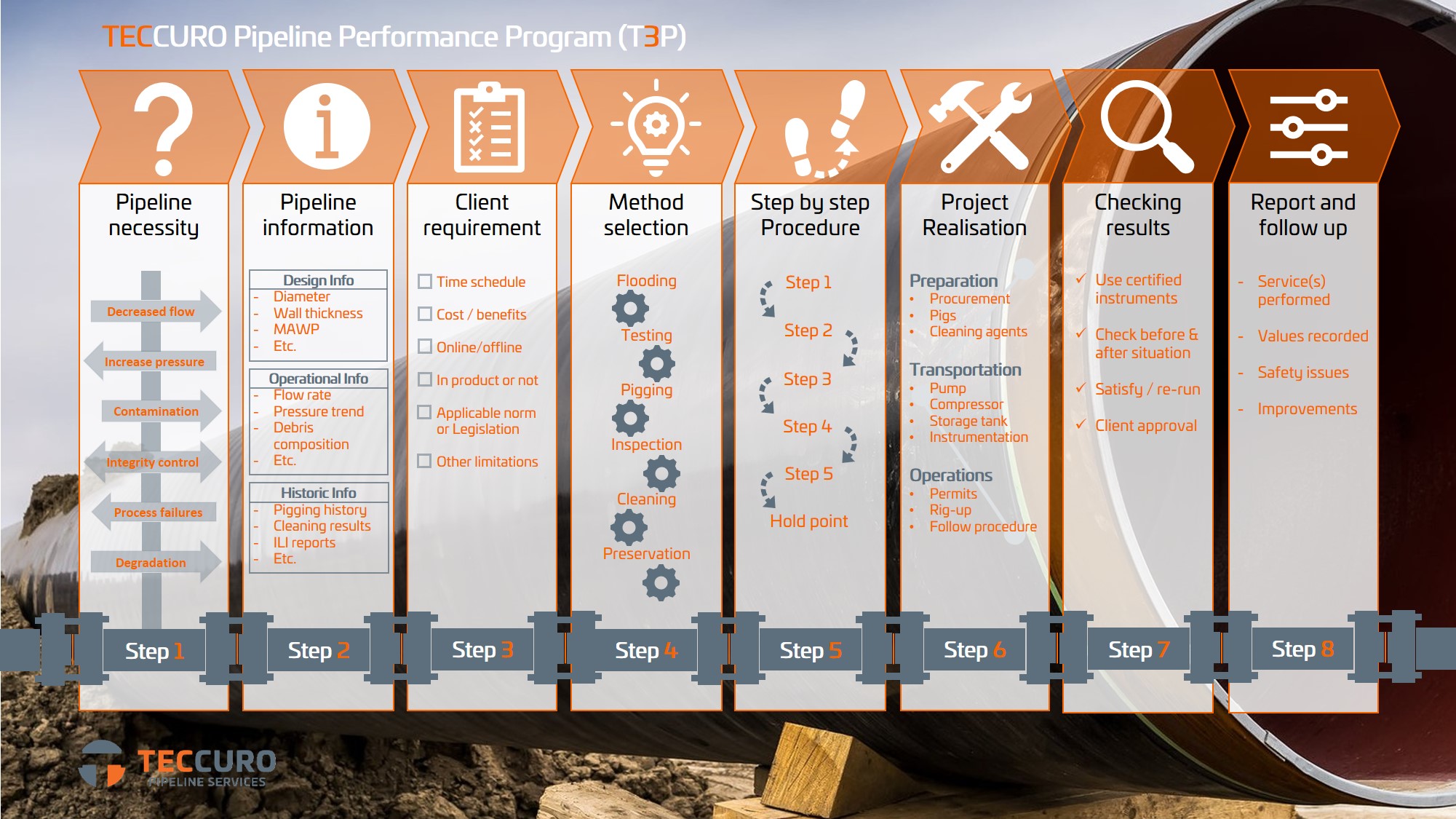

Properly cleaning your pipelines is essential at every stage. Even the smallest contamination in pipelines can damage turbines or instrumentation in a way that the process is no longer functioning correctly and can have severe consequences. Steel pipelines can oxidize and form a layer of rust. Mill scale that is formed during the production process can come off during the process due to the influence of heat or chemicals. Contaminants in the product can precipitate during transport and reduce the diameter of the pipeline. But also human errors can create new challenges. TECCURO has several cleaning options to get your pipeline in optimal condition. For this TECCURO uses the following step-by-step plan that will contribute to the success of your cleaning operation.

Flushing

Flushing pipelines and pipe systems with a liquid to remove the loose contamination is called flushing. Any liquid can be used for rinsing, but water is often used for safety reasons. The result strongly depends on the pipe configuration and customer requirements. A turbulent cleaning flow will provide a better cleaning effect than a laminar flow. The cleaning result can be checked afterwards in various ways (e.g. visually). If you do not have or do not want to use your own product pumps to perform the flushing activities, TECCURO can organise mobile water pumps for you to reach the desirable flows.

Air or nitrogen blowing

In some cases, like gas pipelines, it is not recommended to use water for cleaning. These pipelines are sometimes hard to dry, like after a hydrostatic test. In some cases these pipelines are not constructed to carry the weight of the water. To keep these pipes dry, high velocity air or nitrogen blowing is a good solution to remove the loose fouling. Please note that if nitrogen is being used, extra precautions measurements are necessary. The benefit of using nitrogen is that during the cleaning, the oxygen is purged from the pipelines at the same time.

Pigging

Sending pigs (cleaning tools) through a pipeline has the advantage that the pig, unlike flushing a pipe, puts a mechanical force on the pipeline wall. This makes it possible to loosen the pollution that is stuck to the pipeline wall. There are many pig suppliers in the world who have made a different pig designs for every specific type of contamination. For example, there are pigs that remove rust with brushes, but there are also pigs that remove the wax from a pipeline. In cooperation with you, TECCURO will select the pigging method that will give the best cleaning result for your pipeline.

Chemical cleaning

There are pipelines that need extra treatment to achieve the desired result. During the pigging of a pipelines, bypass can occur. This way some product will be left inside the pipe. The product that is left behind can evaporate and cause gas concentrations that rises above the Lower Explosion Limit (LEL). This can lead to dangerous situations during maintenance work. Chemicals can bind the hydrocarbon molecules and keep the pipeline in a safer condition.

Chemicals can also help during testing and preservation of your pipeline which limits corrosion. Most pipes are tested with water, but if the outside temperature is below zero, testing with only water is not an option. Depending on the available time, TECCURO can, in consultation with you, add a chemical to prevent the water from freezing. TECCURO’s chemicals can also cause the water to be treated, for example during testing and pigging, to significantly slow down the corrosion process in pipes that are difficult to dry.