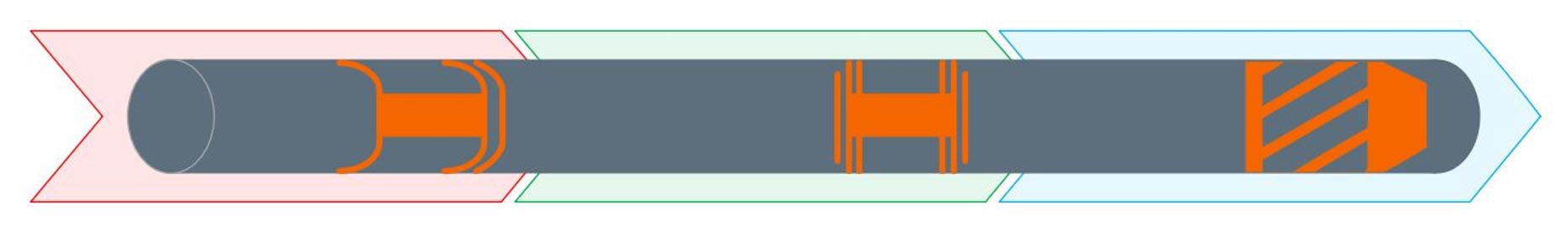

– Multiple purposes in one go

– Short turnaround times

– Various types of separation pigs

In multi-product pipelines, batch pigging is used to ship different products, separated from each other, through the same pipeline. TECCURO also uses this technique to clean pipelines and take them out of service for maintenance in an effective way (decommissioning). The advantage of batch pigging is that multiple cleaning and displacement activities take place simultaneously. By combining different actions into one batch train, TECCURO reduces your total turnaround time.

By removing the product from the pipeline, cleaning and degassing it with chemicals in the same run, offshore and onshore production pipelines can be maintained quickly and effectively.

The advantage of batch pigging is that the work can be done more efficiently, because multiple cleaning actions can take place at the same time. If a pipeline has to be cleaned with chemicals, the entire pipeline needs to be filled. This can be an option for pipelines with a small diameter and short distances, but is not viable for pipelines with large diameters and longer distances. The costs for the amount of chemicals needed and the chemical waste would be far too much. TECCURO provides the option of batch pigging in these situations. With this, a predetermined amount of chemicals is adjusted to the pigging conditions in order to find the right mix between the maximum cleaning result and a minimal amount of chemical fluids.